For on-shore transmission pipelines in an HCA, Class 3 or 4 location without Traceable, Verifiable…

Material Verification Intelligence – A new program to help pipeline operators

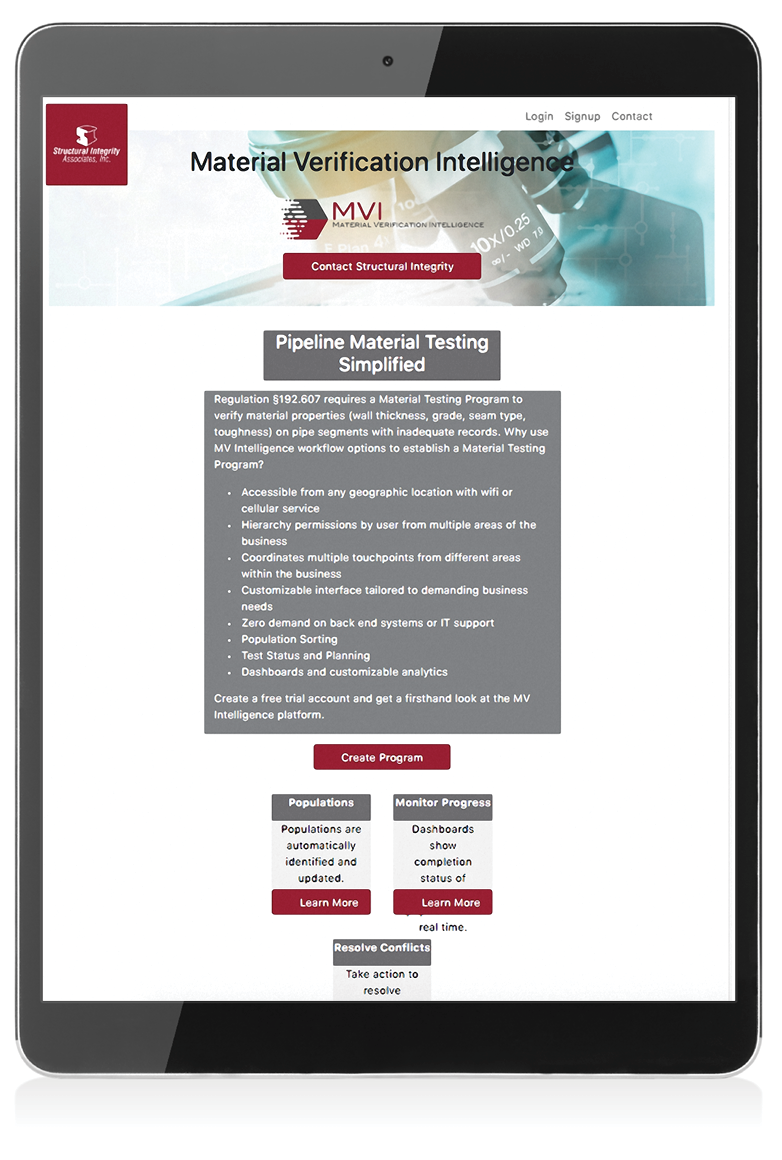

A new program to help pipeline operators implement the Material Verification requirements in recently released pipeline regulation (Mega Rule).

On October 1, 2019, the Pipeline and Hazardous Materials Safety Administration (PHMSA) published the long-awaited Mega-Rule (Part 1). One of the major new requirements identified in these amendments is when missing traceable, verifiable, and complete records, operators must implement a Material Verification (MV) (§192.607) program. MV requires operators of natural gas transmission pipelines, to develop and implement procedures to verify the material properties and attributes of their pipeline system. Included in the new regulation for MV are:

- Develop procedures for conducting destructive and non-destructive testing

- Define population groupings and implement sampling programs

- Implement and document laboratory testing

- Complete in situ and non-destructive evaluations (NDE)

- Expand sampling if inconsistent results based on NDE and laboratory testing

- Document program results and preserve for the life of the pipeline asset

![]()

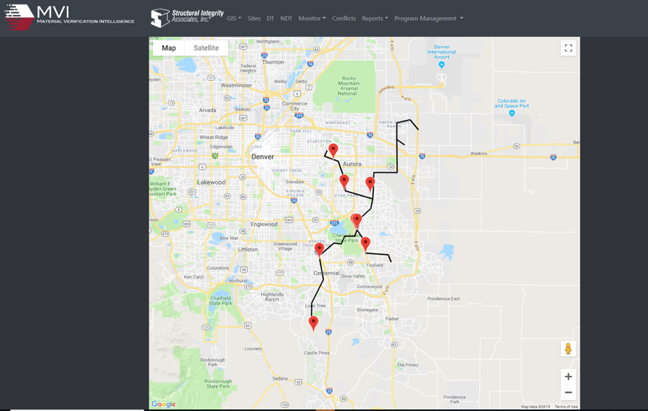

These MV requirements will create new data management challenges in terms of different departments, laboratories, and subcontractors requiring different levels of access to information and different needs to update information as results of the verification process are completed. For example, Integrity Managers and Engineers may be responsible to develop procedures, identify populations, and make decisions based on results of testing; however, operational personnel may make the decision on the selection and testing of test sites; while laboratory and NDE subcontractors perform the actual material testing. Often these stakeholders will likely reside in different offices and/or geographic locations and all have requirements to view, upload, and analyze information in different ways.

In addition to data management issues, the ability to ensure compliance and track progress through implementation of the MV process pose additional challenges. Pipeline operators will need the ability to quickly view and analyze MV results and communicate decisions when inconsistencies are identified.

To help address these challenges, Structural Integrity has developed a new tool, Material Verification Intelligence (MVI), as a web-based application that can help identify and organize essential data and ensure implementation is aligned with supporting MV procedures. MVI is intended to help operators with two main strategic goals: efficiency and speed. MVI automates the comparison of MV results to specified or required values, notifies individuals on availability of information (including inconsistencies identified) and provides an intuitive dashboard to view key performance indicators and results.

By automating many of the repetitive calculations, operators can focus resources where they are most needed. MVI also ensures consistency and quality of the results with little labor input needed. Continuous monitoring of the program status allows an operator to always act based on the most up-to-date information – whether the use of that information is selecting integrity digs, selecting material testing methods, fitness for service, MAOP, or other purposes.

The material testing program is not a one-time, linear process but rather a continuous, cyclical one. Populations are continually updated as new data becomes available, and segments can move between populations as identified. Thus, a one-time population definition is not enough – operators will need to re-evaluate populations continuously. When conflicts arise (as when material testing data does not confirm record data), an operator using MVI can be notified immediately and respond accordingly.

To get started with MVI, visit mvi.structint.com. If you wish, an SI expert can assist you with developing the required MV procedures, support program setup and management.

Steven Biles – sbiles@structint.com

Scott Riccardella – sriccardella@structint.com

Comments (0)